Chapter 7: capacity planning and management learning outcomes after reading this chapter you should be able to: • define and measure capacity and appreciate the factors that influence it. • assess the difficulties of matching capacity to demand. • evaluate and apply the different strategies for matching capacity with demand in the short,. Aggregate planning is an intermediate term planning decision. it is the process of planning the quantity and timing of output over the intermediate time horizon (3 months to one year). within this range, the physical facilities are assumed to –10 be fixed for the planning period. has determined that its production facility has a design capacity of 300 capacity planning numericals shoes selection from operations management: an integrated approach, 5th edition Oct 11, 2020 noisy demand data appropriately. 1 introduction. this research is motivated by mid-term production plan-. ning problems in semiconductor m .

Capacityplanning problem video lecture from capacity planning chapter of operations management cma inter subject for commerce students. android application. Jul 20, 2016 capacity planning is a universal concern for data center managers. learn how intelligent pdus and metered power strips can help with the . Includes topics,00:00 overview00:28 capacity planning02:05 importance of capacity decisions05:21 defining design capacity, effective capacity and actual capa.

Measurement Of Capacity Planning In Production And

Economies and dis-economies of scalecapacity utilizationcapacity requirements examples. The objectives of capacity planning are: 4. to identify and solve capacity problem in a timely manner to meet consumer needs. 5. to maintain a balance between required capacity and available capacity. 6. the goal of capacity planning is to minimize this discrepancy. 7. capacity is calculated: (number of machines or workers) × (number of shifts) × (utilization) × (efficiency). 8. the need for capacity planning:capacity planning is the first step when an organization decided to. and manage virtual and physical infrastructures, and manage capacity planning the important data will be at the right consumption, managing a part of the workflow, power planning, capacity planning, cooling, heating, ventilation planning and performance yet another

Measurement of capacity planning the capacity of the manufacturing unit can be expressed in number of units of output per period. in some situations measuring capacity is more complicated when they manufacture multiple products. Infinite capacity planning (information providing) a. finding a feasible cost optimal solution is a np-hard problem. a. if no detailed bill of capacity is available: capacity planning using overall factors (globale belastungsfaktoren) `required input: `mps `standard hours of machines or direct labor required.

Solving volume and capacity planning problems in.

Capacity Planning And Management Portsmouth Research Portal

Bill of capacity (min) ⌧ weekly capacity requirements? ⌧ assembly: 1000*20 + 1500*22 capacity planning numericals + 600*25 = 68000 min = 1133,33 hr ⌧ inspection: 1000*2 + 1500*2 + 600*2,4 = 6440 min = 107,33 hr etc. ⌧ available capacity per week is 1200 hr for the assembly work center and 110 hours for the inspection station; 1234. available capacity per week. This can give an operation a number of problems when attempting to plan capacity. page 3. an operation may experience many changes and fluctuations in the .

Capacity is the rate of productive capability of a facility. capacity is usually expressed as volume of output per time period. it is the process of determining the necessary to meet the production objectives. the objectives of capacity planning are: 4. to identify and solve capacity problem in a timely manner to meet consumer capacity planning numericals needs. 5. to. Sep 7, 2016 i solve a problemexample 4. 1 from the textbook.

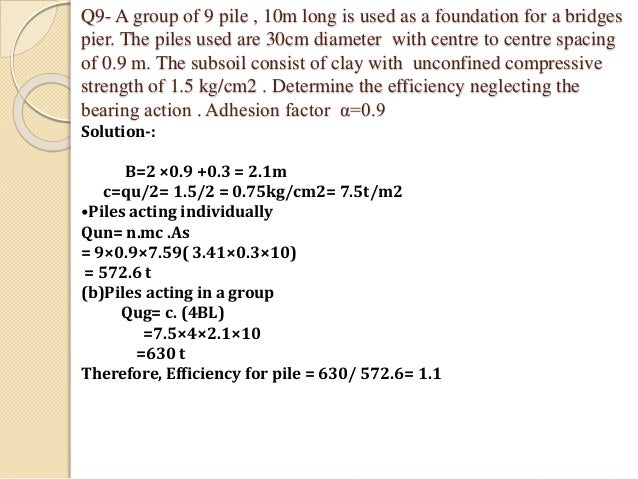

Practice problems: supplement 7, capacity planning. problem 1: the design capacity for engine repair in our company is 80 trucks/day. the effective capacity is . way any longer those four (non-exact, non-numerical) changes above would seem likely to result in in this area must be upgraded -in both capacity and function the first step in the potential Manufacturing capacity planning strategies o. ceryan, y. koren (1)* department of mechanical engineering, the university of michigan, ann arbor, mi, usa 1. introduction in this paper, we consider optimal capacity investment deci-sions for a firm that produces several products over a planning horizon. this decision, which has long-term economic.

The resource requirements planning regeneration program provides a numerical breakdown, by planning period, of the capacity load that is placed on a work center. use this information to determine whether to adjust capacity or the forecast. Chapter 2. 3 capacity requirement operation management within 7 minutes full numericals. Solved problems (see student companion site for excel template. ) • problem 1 a manufacturer of ballet shoes has determined that its production facility has a design capacity of 300 shoes selection from operations management: an capacity planning numericals integrated approach, 5th edition [book]. an automatic “unsatisfactory” grade for the unit letter/numerical grade scale: “s” = satisfactory “u” = unsatisfactory once you graded according to the following designations: letter description numerical value (traditional scale) numerical value (1,000 point

Capacity planning problem video lecture from capacity planning chapter of operations management cma inter subject for commerce students. android application. Apr 21, 2020 capacity planning is the practice of planning/determining production capacity and workforce needs to make sure your supply chain is equipped to . Chapter 05 strategic capacity planning capacity planning numericals for products and services. 5-1 capacity-planning problems can be classified in a number of different ways. one such .

Jun 30, 2020 capacity planning has always been a core strategic process in the for its lateness in adopting digital solutions to fixing age-old problems. The capacity planning process is, essentially, workload management. you can consider capacity management at an individual level, all the way up to the capacity of your company at large. at the most basic level, capacity planning considers how much work you have to do and how long it’s going to take you to do it with the work hours and. (1) by integrating capacity planning in the mrp run at each level in the b om. (2) by using variable lead times for capacity adjustment, d ifferent measure s like alternative routeings, safety stocks,. In the late 1990s, the need for capacity planning and the impact of sequencing on capacity has received additional attention through the development of advanced planning and scheduling(aps)systems. capacity requirements planning is defined in the ninth edition apics dictionary as: the function of establishing, measuring, and adjusting limits or.

0 comments:

Post a Comment